Dividing head vs rotary table – As dividing heads and rotary tables take center stage, this opening passage beckons readers into a world crafted with good knowledge, ensuring a reading experience that is both absorbing and distinctly original.

The content of the second paragraph that provides descriptive and clear information about the topic

Definition and Overview

Dividing heads and rotary tables are both essential tools in the machining industry, but they serve different purposes.

Dividing Heads

Dividing heads are used to hold workpieces in place while they are being machined. They are typically used for operations such as milling, drilling, and grinding. Dividing heads allow the workpiece to be rotated to a specific angle, which allows the machinist to create precise cuts.

Rotary Tables

Rotary tables are similar to dividing heads, but they are used for different purposes. Rotary tables are used to rotate workpieces around a vertical axis. This allows the machinist to access all sides of the workpiece, which is useful for operations such as welding, assembly, and inspection.

Applications

Dividing heads and rotary tables are used in a wide variety of industries, including the automotive, aerospace, and medical industries. They are essential tools for any machine shop.

Construction and Design: Dividing Head Vs Rotary Table

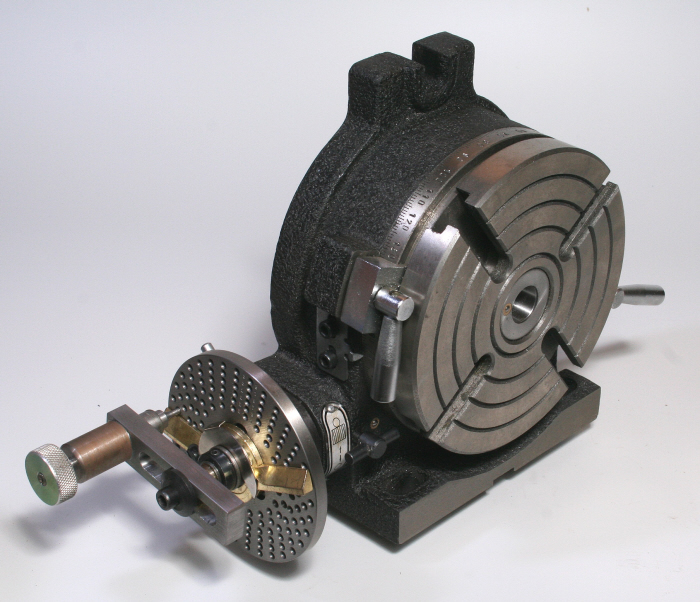

Dividing heads and rotary tables share similar construction materials and design principles, but with distinct features tailored to their respective functions.

Both devices are typically constructed from durable materials such as cast iron or steel to withstand the rigors of machining operations. The base of the device provides a stable foundation, while the head or table rotates on precision bearings to ensure smooth and accurate movement.

Key Components and Functions

Dividing heads consist of a spindle, index plate, and tailstock. The spindle holds the workpiece, while the index plate is used to divide the circle into equal parts. The tailstock provides support for the workpiece during machining operations.

Rotary tables, on the other hand, have a rotating table that can be positioned at various angles. They often feature scales and verniers for precise angular measurement and adjustment.

Types and Variations

Dividing heads and rotary tables come in a range of types and variations, each tailored to specific applications. Understanding these variations is crucial for selecting the right tool for the job.

The primary distinction between dividing heads and rotary tables lies in their primary function. Dividing heads are primarily used for precise angular indexing, while rotary tables offer continuous rotation and are often used for machining operations like milling and grinding.

Dividing Heads

- Universal Dividing Heads:These versatile dividing heads allow for dividing a full circle into any number of equal parts. They feature adjustable index plates and tailstocks for precise positioning.

- Vertical Dividing Heads:Designed for vertical mounting, these dividing heads are commonly used for milling and drilling operations. They offer high accuracy and can handle heavy workpieces.

- Optical Dividing Heads:Equipped with optical scales, these dividing heads provide exceptional precision for applications requiring extreme accuracy. They are often used in toolmaking and precision machining.

Rotary Tables

- Horizontal Rotary Tables:Mounted horizontally, these rotary tables provide continuous rotation and are ideal for milling, drilling, and other machining operations. They often feature T-slots for workpiece mounting.

- Vertical Rotary Tables:Designed for vertical mounting, these rotary tables are suitable for operations like surface grinding and indexing. They offer high rigidity and can handle large workpieces.

- Tilt Rotary Tables:These rotary tables can be tilted to various angles, making them versatile for machining complex shapes and angles. They are commonly used in aerospace and automotive industries.

Accuracy and Precision

Accuracy and precision are two important factors to consider when using dividing heads or rotary tables. Accuracy refers to how close the actual position of the workpiece is to the desired position, while precision refers to how repeatable the positioning is.There

are several factors that can affect the accuracy and precision of a dividing head or rotary table, including:

- The quality of the bearings and gears

- The backlash in the gears

- The rigidity of the workpiece and the fixture

- The skill of the operator

There are several methods that can be used to achieve high levels of accuracy and precision when using a dividing head or rotary table. These include:

- Using high-quality bearings and gears

- Minimizing backlash in the gears

- Using a rigid workpiece and fixture

- Training the operator on the proper use of the equipment

Accuracy is critical in many applications, such as:

- Machining parts to precise tolerances

- Assembling parts with high precision

- Measuring angles and distances

Applications and Advantages

Dividing heads and rotary tables find extensive applications in various industries and machining processes. They offer precise angular positioning and rotation, making them ideal for operations such as milling, drilling, indexing, and engraving.

When comparing dividing heads and rotary tables, one might find themselves in a vocabulary conundrum. To unravel this enigma, one can delve into words with the root word voc , such as “vocabulary” and “vocation.” Returning to our comparison, dividing heads excel in angular positioning, while rotary tables dominate in continuous rotation.

Both tools are indispensable in the realm of precision machining.

Applications

- CNC Machining:Dividing heads and rotary tables are commonly used in CNC machines for multi-axis machining operations, allowing for complex part geometries and efficient production.

- Manual Machining:They are essential tools for manual machining, enabling precise indexing and rotation of workpieces for operations like milling, drilling, and grinding.

- Gear Cutting:Rotary tables are indispensable for gear cutting operations, providing accurate rotation and indexing for cutting gears with various tooth profiles.

- Welding and Fabrication:Dividing heads and rotary tables are used in welding and fabrication to position and rotate components for precise welding and assembly.

Advantages

Using dividing heads and rotary tables offers several advantages:

- Precision and Accuracy:They provide highly precise angular positioning and rotation, ensuring accurate and repeatable results in machining operations.

- Versatility:Dividing heads and rotary tables can be used for a wide range of applications, from simple indexing to complex multi-axis machining.

- Efficiency:By eliminating the need for manual indexing and rotation, they improve efficiency and reduce production time.

- Reduced Setup Time:The ability to quickly and accurately position workpieces reduces setup time and improves overall productivity.

Case Studies

One notable case study involves the use of a rotary table in the production of precision gears for a high-performance automotive transmission. The rotary table’s accurate rotation and indexing capabilities ensured the precise cutting of gear teeth, resulting in smooth and efficient gear operation.Another

example is the use of a dividing head in a manual milling machine to create intricate engravings on a commemorative plaque. The dividing head’s precise indexing allowed for the accurate and consistent engraving of complex patterns and designs.

Maintenance and Troubleshooting

Regular maintenance is crucial to ensure the accuracy, longevity, and optimal performance of dividing heads and rotary tables. Neglecting maintenance can lead to premature wear, decreased accuracy, and potential safety hazards.

A comprehensive maintenance schedule should be established based on the manufacturer’s recommendations and the frequency of use. This schedule should include regular cleaning, lubrication, inspection, and calibration.

Maintenance Schedule

- Daily:Clean the dividing head or rotary table and remove any chips or debris.

- Weekly:Lubricate the moving parts, such as the spindle bearings, worm gears, and lead screws.

- Monthly:Inspect the dividing head or rotary table for any signs of wear, damage, or misalignment.

- Annually:Calibrate the dividing head or rotary table using a precision indicator or other suitable equipment.

Common Troubleshooting Issues, Dividing head vs rotary table

- Inaccurate indexing:Check the worm gear and lead screw for wear or damage. Adjust the backlash or replace the worn components.

- Table runout:Check the spindle bearings for wear or damage. Adjust the preload or replace the bearings.

- Excessive backlash:Adjust the backlash between the worm gear and lead screw. Replace the worn components if necessary.

- Table not rotating smoothly:Lubricate the moving parts. Check for any obstructions or misalignment.

Comparison and Contrast

Dividing heads and rotary tables are both precision devices used in machining and fabrication. However, they differ in their construction, capabilities, and applications.

The following table compares the features and capabilities of dividing heads and rotary tables:

| Feature | Dividing Head | Rotary Table |

|---|---|---|

| Construction | Mounted on a machine table or base | Mounted on a horizontal or vertical axis |

| Capabilities | Indexing, dividing, and milling | Indexing, rotating, and positioning |

| Accuracy | High accuracy (typically within 0.001 degree) | Moderate accuracy (typically within 0.005 degree) |

| Precision | High precision (typically within 0.0005 degree) | Moderate precision (typically within 0.001 degree) |

| Applications | Precision machining, gear cutting, milling | Positioning, assembly, inspection |

Factors to Consider When Choosing

When choosing between a dividing head and a rotary table, consider the following factors:

- Accuracy and precision requirements:Dividing heads offer higher accuracy and precision than rotary tables.

- Indexing capabilities:Dividing heads are designed for precise indexing, while rotary tables are more versatile for rotating and positioning.

- Application:Dividing heads are ideal for precision machining and gear cutting, while rotary tables are suitable for a wider range of applications, including positioning, assembly, and inspection.

FAQ Explained

What is the difference between a dividing head and a rotary table?

A dividing head is a precision indexing device used for dividing a circle into equal parts. A rotary table is a rotating platform that allows for the precise positioning of a workpiece.

What are the advantages of using a dividing head or rotary table?

Dividing heads and rotary tables offer increased accuracy and precision in machining operations, enabling the creation of complex parts with tight tolerances.